What Are You Looking For?

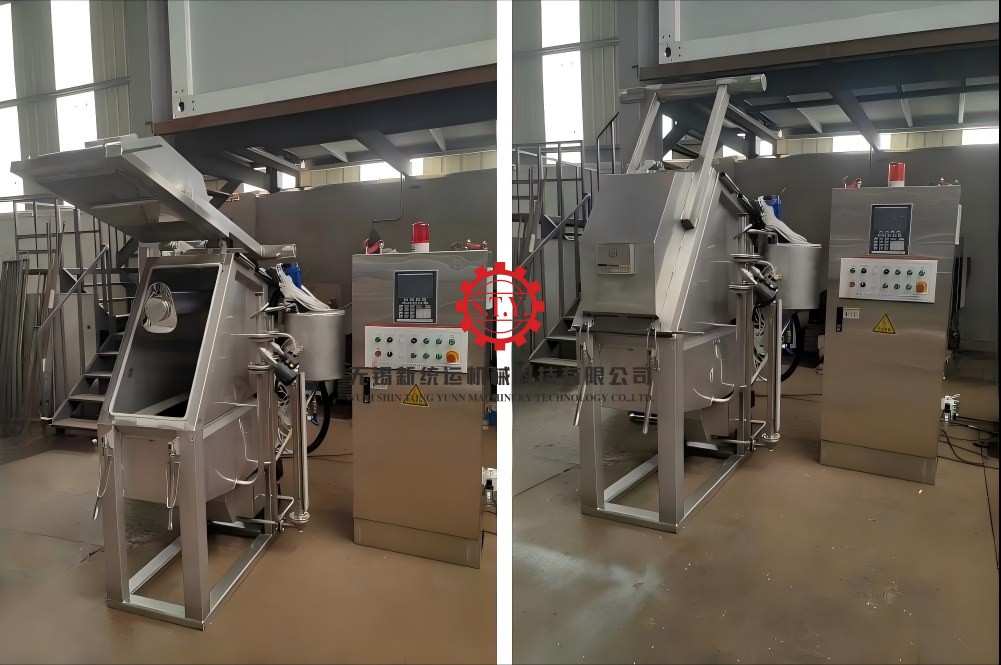

SH-1-65 hank dyeing machine is electric heating yarn dyeing machine, it's specifically designed for sampling, small-order production and large-dyeing machine simulation. The compact yarn dyeing machine(capacity:4-6KG) delivers same consistent and high-quality dyeing result as large industrial dyeing machines. But unmatched flexibility and efficiency for specialized applications. It's the perfect small batch yarn dyeing solution for R&D lab, specialty textile producers and large mills seeking to optimize their production workflow.

Model :

SH-1-65(electric heating)Payment :

T/T; L/CProduct Origin :

ChinaShipping Port :

Shanghai Port, China

We foucus on providing reliable hank dyeing machine for sampling and small lot yarn dyeing. Allowing manufacturers to produce tiny quantities cost-effectively. At the same time, ensuring color accuracy and quality that can be perfectly scaled up to larger production machines.

SH-1-65 works as an excellent pilot scale yarn dyeing machine, enabling dyeing factory to test new color, yarns and dyeing recipe with minimal material waste. Its precise temperature control ensures perfect color matching for yarn dyeing, guaranteeing small sample batch accurately reflects what will be achieved in full-scale production.

The key advantage of SH-1-65, it can be used as lab scale yarn dyeing machine that accurately simulates large machine dyeing result. By using this machine for prototyping, you can finalize dyeing parameter and anticipate outcome before committing to large & expensive production run, thereby reducing risk and saving cost.

Every aspect of the SH-1-65 is manufactured to support reliable and repeatable small-scale dyeing operations.

Main part of electric sample dyeing machine is high-performance heating system. Electric heating system is constructed from durable stainless steel 316 seamless tubes, ensuring superior corrosion resistance, long service life and consistent heat transfer for even dyeing in every small batch.

To maximize productivity in sampling and small batch dyeing environment, we designed a rapid cooling system. It reduces the cycle time between batches, allowing you to complete more tests or small orders per day and accelerate your time-to-market.

Main body of yarn dyeing machine can be constructed from either stainless steel 304 or stainless steel 316, based on you choose level of chemical resistance required for your specific dyes. This customizable hank dyeing machine approach ensures the equipment meets your exact operational need.

SH-1-65 is not only a textile dyeing machine, but also a strategic tool for:

Investing SH-1-65 means investing in precision, flexibility and cost-saving efficiency for your small-batch dyeing demands. It bridges the gap between dyeing lab and factory floor, ensuring perfect results from sample to bulk production.

| MODEL | CAPACITY(KG) | NO. OF SPRAY PIPE | MAIN POWER(KW) |

| SH-1-65 | 3 | 1 | 1.1 |

| SH-2-65 | 7 | 2 | 1.1 |

| SH-2-120 | 14 | 2 | 1.5 |

| SH-4-120 | 28 | 4 | 3 |

| SH-6-120 | 42 | 6 | 4 |

| SH-10-150 | 100 | 10 | 5.5 |

| SH-20-150 | 200 | 20 | 11 |

| SH-30-150 | 300 | 30 | 18.5 |

| SH-40-150 | 400 | 40 | 22 |

TEXTILE DYEING MACHINE MANUFACTURER IN CHINA - WUXI SHIN TONG YUNN MACHINERY TECHNOLOGY CO., LTD

Tags :